Corrugated blades, originating from Japan, are specialized tools primarily designed for shaving eyebrows and trimming hair. The term “corrugated” refers to the distinctive wavy pattern on the blade’s surface. Predominantly crafted from carbon steel, these blades are affordable and ideal for single-use applications, offering both cost-effectiveness and hygiene. This combination has made them a favored choice among consumers.

Corrugated blade video

Materials and Pricing

Corrugated blades come in various materials, each with unique properties and corresponding price ranges:

- 65M Carbon Steel: The most prevalent material in the domestic market, constituting about 80% de Xirui supply of corrugated blades. Factory prices range from 485 Para 600 RMB per box.

- 214 Stainless Steel (4Cr13): Sharper and more durable than carbon steel, this material is popular with brands like Miniso and clients requiring custom packaging. Factory prices are between 1100 e ainda 1500 RMB per box.

- 216 Stainless Steel (6Cr13): The highest-quality option currently produced, offering superior performance. Factory prices vary from 1500 Para 2500 RMB per box, influenced by order volume.

Corrugated Blades Customization Recommendations

Usage Scenarios

Corrugated blades are versatile and suited for multiple applications:

Shaving Eyebrows:

- Clean the eyebrow area with a cotton pad or alcohol wipe.

- Define the desired eyebrow shape and use the blade to remove hair outside the contour.

With a Holder: Paired with a holder, these blades can be used for shaving and haircutting.

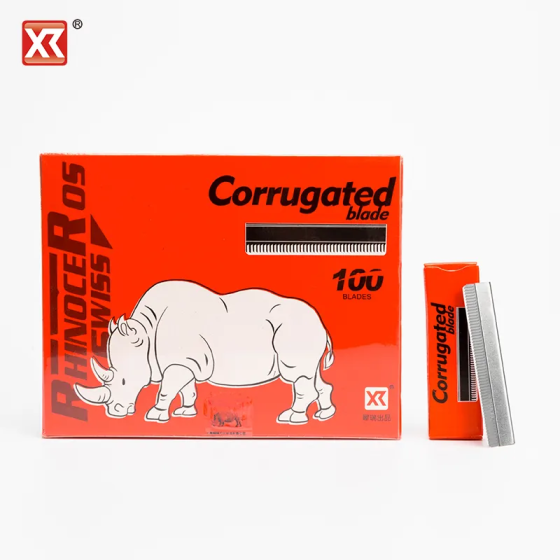

Packaging Methods

The most common packaging options for corrugated blades include:

- Standard Packaging: Each blade is wrapped in white or custom paper strips, com 10 blades per small box, 10 small boxes per medium box, e ainda 100 medium boxes per carton.

- Loose Packaging: Omitting medium boxes, this method packs 10 blades per small box. It’s popular among e-commerce clients on platforms like Douyin or Pinduoduo, who pair them with products like blade holders.

For 65M carbon steel blades, factory prices range from 485 Para 600 RMB per box, depending on order size. For example, single-box purchases cost 560-600 RMB, while orders of 200 boxes or more may drop to 490 RMB per box.

Custom packaging options are also available:

- Small boxes packed into custom OPP composite bags.

- Paper cards with blister packs.

- Tailored sets designed to meet specific client needs.

Corrugated Blades Production Process

The manufacturing of corrugated blades involves a detailed sequence of steps:

- Stamping

- Heat Treatment

- Grinding

- Cleaning

- Chrome Plating

- Teflon Coating

- Soaking in Anti-Rust Oil

- Automatic Assembly

- Manual Boxing

For stainless steel variants, additional processes—extra cleaning, chrome plating, and Teflon coating—are included to enhance quality and performance.

Corrugated Blades Technical Parameters

Key specifications for corrugated blades are as follows:

Espessura da lâmina:

- Industry range: 0.13mm to 0.15mm

- Factory standard: 0.13mm to 0.15mm

Finished Hardness (HV):

|

Material |

Industry Minimum |

Industry Average |

Factory Standard |

Industry Maximum |

|---|---|---|---|---|

|

General |

540 HV |

– | – |

680 HV |

|

214 Stainless Steel |

– |

560 ± 40 HV |

580 ± 30 HV |

– |

|

216 Stainless Steel |

– |

620 ± 40 HV |

650 ± 30 HV |

– |

Sharpness (N):

- Industry minimum: Approximately 12 N

- Industry average: Approximately 17 N

- Factory standard: Less than or equal to 18 N

These parameters ensure the blades meet essential standards for durability, sharpness, and safety.

Xiruiglobal.COM

Xiruiglobal.COM